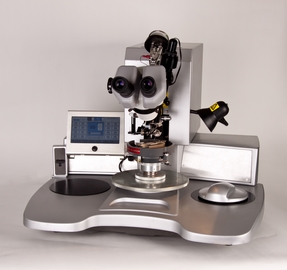

Budget sensitive Manual Die Bonder

Budget sensitive Manual Die Bonder

The T-4909-AE is Tresky's 40-year anniversary model. On basis of the T-4909 we developed a new software running on an integrated Raspberry PC. Like all Tresky Die Bonder this pick & place system operates with True Vertical Technology™. The increased travel range, now 95mm on Z, allows working on various bonding heights for Epoxy-, Eutectic- and Flip-Chip processes.

Die Bonder

Dr. Tresky AG

- TRUE VERTICAL TECHNOLOGY™ with 95mm Z-movement

- Simultaneous viewing of two objects by an optical overlay (superposition) on the monitor.

- Touchscreen for selection of pick & place, dispensing, stamping

The iBond5000 Series integrates the 4500 manual wire bonder mechanical design with an advanced graphical user interface. The iBond5000 Series includes 3 basic models: Wedge, Ball and Dual. The iBond5000-Ball is an advanced ball bonder used for process development production, research or added manufacturing support. The iBond5000 provides the high yield and excellent repeatability needed for every gold ball bonding application including: Optoelectronic Modules, Hybrids/MCMs, Microwave Products, Discrete Devices/Lasers and much more.

Manual Wire Bonder

Micro Point pro

- 7” TFT Touch Screen Management

- 800MB Capacity

- Windows CE-based management software

- Internal Tools database

- Large 6” X 6” bonding area

- Built-in temperature controller

The second generation Nordson DAGE 4000Plus is the most advanced bondtester on the market. Representing the best-in-class, the 4000Plus bondtester sets the industry standard in bond testing offering unsurpassed accuracy and repeatability of data, providing complete confidence in results.

4000Plus Bondtester

Dage

- Highly Versatile

- Switch Applications in Just Seconds

- Increased Efficiency

- Ultimate Step Back Accuracy

- Correlation

- Intelligent Software

State-of-the-art plasma treatment in a compact, bench-top configuration The AP-300 plasma system from March Plasma Systems is designed to deliver exceptionally uniform plasma cleaning and treatment with unmatched ease of operation, reliability and low cost.

Nordson March Plasma cleaning - AP-300 plasma system

Nordson DAGE

- Completely self-contained

- Automatic matching network

- High-quality aluminum with aluminum fixtures

- Superior durability

- Grounded shelves to accommodate a wide range

The NEW Quadra? 5 is the ultimate flexible X-ray inspection solution designed specifically for the electronics market.

X-Ray Inspection - Quadra-7

NORDSON DAGE

- Leading core technology

- High performance and ease of use

- Leading choice for printed circuit board and semiconductor package inspection.

- 0.35μm (350nm) Feature Recognition up to 10 W Tube power

- Total Magnification 45,000 X

- AχiS - Active X-ray Image Stabilisation

Accurex offers along with KIT Innovation co ltd for the Mobile Camera Module Lens assembly Inspection and testing systems, Bonders which can Simultaneous attach and do the bonding using Dual Head, offers the Turnkey solution for Assemble the lens part such as (barrel, lens, spacer) that goes into the camera module. KIT inoovation have developed and supplied equipment that plays a key role in the precise camera module process..

Camera Lens Module Assy Machine

KIT Innovation Co., Ltd.

- Engage the lens module at a constant height to the VCM housing using precision vision technology

- Torque control and precision laser sensor are applied to prevent parts from being damaged and to realize precise tightening height control

- Apply two tightening units to increase productivity

- Precision stage for fine-tuning to correct processing errors of lens jigs is applied in addition to the basic driveshaft

- Gore cables and anti-foreign measures are applied to minimize foreign substances generated during facility operation.

Offers World-class BGA Solder Ball Attach System with Vision(Pattern Recognition System) to recognize fiducial mark and does Flux dotting and Ball attach, with in-built Flux dipping, Flux Heating, Flux dotting configuration, with auto ball pick up with vision Inspection and ball attach based on PRS Data.

Solder Ball Attach

Koses

- Length: 180 ~ 250mm / Width: 30 ~ 100mm

- Free Fall(Gravity) or Ejector Pin Pushing

- PRS(Patten Recognition System) Vision Alignment

- Dual Shuttle(Front/Rear)

For high volume production

For high volume production

For high volume production

MRSI Systems

- 1.5 micron die bonding For high volume production

- Fully automated, high-speed, high-precision, high flexibility

- Scaling applications, ultimate speed

- High Volume Solutions

- The MRSI-HVM Family is the best-in-class die bonder, offering leading speed, zero-time tool change, and <1.5 micron accuracy.

- The MRSI-H Family provides proven superior flexibility for true multi-die, multi-process, multi-product high-volume high-mix production with <1.5 micron accuracy.

For high volume & flexible production

For high volume & flexible production

From prototype to mass production, our team has the know-how to support your needs. CMAT’s ability to deliver consistent, reliable results is unmatched with typical yields close to 100%. Our market leading position is built on our ability to scale whilst maintaining quality and accuracy. Over 60 million actively aligned units are produced by our customers using our systems every year.

Camera & sensor assembly and test system

AEI

- Optimizing performance

- Seamless integration – systems and people

- Field proven reliability and quality

- Return on investment

A reliable partner in your progress

© 1997 - 2020. Accurex Solutions Pvt. Ltd.