Yuni

YUNI

yuni-ele.com

- SMEMA Compatible

- Micro-computer based

- Compatible to all standard PCB Machines

- LCD Monitor for user friendly operation

Jet printing flexibility for higher profitability

Using a revolutionary new technology for solder paste application, the MY700 shoots solder paste on the fly without touching the PCB. Because it needs no stencils, it offers many advantages over the standard screen printer – like more PCB design freedom and virtually no changeover or lead times. Solder paste deposits can be adjusted on-the-spot in three dimensions. The future of SMT production is increasingly complex. Denser boards, a wider range of miniaturized components, more NPIs and erratic production schedules. As these high-mix challenges go mainstream, real productivity and throughput suffer. And we’ve only just seen the beginning. At Mycronic, we’ve devoted decades of experience to solving precisely these challenges. With the industry’s fastest, most flexible and most precise jet printing and dispensing systems.

Jet Printer - My700

Experience New Levels of Printing Freedom

MYCRONIC (MYDATA)

- Dual heads for productivity

- Dual lanes for smart board handling and buffering

- High-speed, high-accuracy dispensing

- Solder paste and a wide range assembly fluids

- Board revisions on-the-fly and changeovers in no time

The placeALL®520 is a modular Pick&Place system and especially useful to build prototypes and small series. It supports a large range of components (chips, FP-components and BGAs), so even the most complex tasks can be handled.

An intelligent software and up to 200 possbile kitting slots minimze changeover times, which increases productivity for small lot sizes. The placeALL®520 can easily be upgraded or integrated into an inline system on Location

placeALL®520 machines

Fritsch

- 100 Slots for 8 or 12 mm single tape FEEDER

- Max. 200 Positions for 8 mm tapes

- Max. 1 assembling head

- Max. 2 dispensing heads

- Optional dividable machine frame

- Max. PCB size: 520 x 430

- Platform 1820 x 1425 x 1570 mm with FEEDER

- Standalone or inline

It's about time

MY300 delivers new levels of precision and flexibility in a faster, smaller and smarter format.

MY300

MYCRONIC

- More capabilities in less factory space

- More process steps with less equipment

- Handle a wider range of products and components

- Less manual operation

- Achieve higher real speed and utilization

High-Accuracy

As HCT SMT Pick & Place Machine that equipped with 8 heads as well as a new flying vision system, the HCT SMT Pick & Place Machine realizes a chip mounting speed of 20,000 CPH. In addition, it is applicable to 0201 chips to the largest 20mm ICs by default and increases actual productivity and placement quality by applying a smart nozzle checking and replacing system.

HCT800

HCT800

- High-Accuracy-Non-stop Recognition by Flying Vision System

- High Repeatability & Stability-Magnetic levitation linear motor in X and Y-axis

- Bottom Vision Alignment system for big components / IC.

- Fiducial recognition and coordinate correction.

- Conveyor system with SMEMA interface and automatic-width-control.

- Smart Nozzle System provides automatic nozzle checking and replacing.

- Strong and rigid mechanical design.

- Self-developed software simplifies production.

Efficient Yet Economical

EPS worldwise's two decades of rich experience brings systems capable of handling complex parameters in our micro - processor and computer controlled products.

SMT Reflow Soldering System RF300 - Table top with Stand

Delivering Cost Effective Reflow Machine

EPS WORLDWIDE

- Superior to batch and other ovens

- Heating zone is programmable through the controller

- Stores up to 100 profiles.

- Real-time temperature profiler port

- Conveyor speed, heating elements hot air flow, and cooling fans are also Programmable

- SPC fault monitoring & reporting

- Pb Free process is possible

- Temperature can go up to 300C

For Continuous Production

For Continuous Production

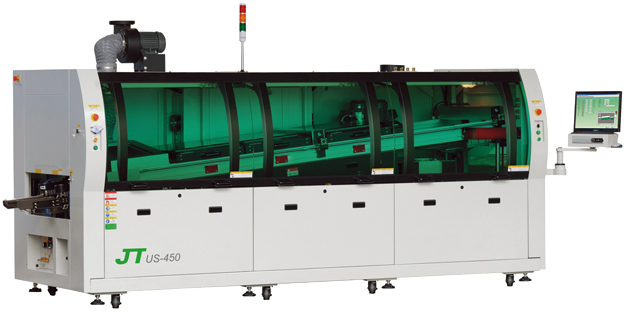

Shenzhen JT Automation Equipment Co., Ltd. was founded in 2004 with registered capital of 60 million Yuan. Self-development, production, operation: first, Electronic assembly machine and other associated equipment, including lead-free wave soldering, lead-free reflow soldering, 3D/2D vision inspection equipment, dispenser, rework station, loading and unloading machines and other products, which are necessary equipments for circuit board assembly line in the consumer electronics, communications, automotive electronics, aerospace, defense electronics and other fields; Second, solar photovoltaic equipment, including all necessary main production equipments for solar cell production line.

JT EQUIPMENT - JTR and RS Series

User Friendly, 24/7 Operation

JT EQUIPMENT

- PLC controlled

- Hot Air Reflow - 8 / 10 Zones

- High Heat Efficiency

- Every Minute Every Second Profiling - build in KIC 24/7

- Zero Defect Thermal Process

- Intelligent Diagnosis System

Energy Efficient

The smallest unit with the time-tested Quattro Peak technology. Ideal for the highest demand on quality and efficiency for medium throughput.

SMT GmBH

Highest Demand on Quality & Efficiency

SMT GmBH

- Forced Convection

- Quattro-Peak Technology

- Power nozzle system for optimal heat transfer

- Multistage condensate filter at cooling zone

- Suitable for temper and curing processes

Efficient Yet Economical

Automatic wave solder system with self-contained fluxing, preheating and laminar (smooth) solder wave modules

EPS WORLDWIDE - WSM 180/300 Single & Dual Wave Soldering Machines

Delivering Cost Effective Wave Soldering Machine

EPS WORLDWIDE

- Automatic wave solder system

- Best value through cutting-edge technology

- Ready-to-go fluxing, preheating and wave modules

- Quick ROI (Return on Investment)

- Exceptional accuracy and repeatability

- Lead or Lead-Free solder compatibility

- Easy to use

- Low maintenance

For Continuous Production

Spray areas set convenience, optional auto optimizing the route of spray, point-fully spray model transition freely, closed loop control

JT EQUIPMENT - WS series

User Friendly, 24/7 Operation

JT EQUIPMENT

- PLC / PC controlled

- Magnetic Hydro Dynamic Solder Pump

- Pb Free Compatible

- Pre-heaters forced air convection

- Spray / Ultrasonic Fluxer

- Quick Change Type Finger

High Performance Selective Soldering machine

Pillarhouse International are world leaders in the Selective Soldering industry, dedicated to the ongoing development of pioneering technologies, such as our patented 1.5mm Micro Nozzle, to reflect and match the needs of an everchanging manufacturing marketplace.

Selective Soldering

Pillarhouse

Designed to meet the needs of lean manufacturing

- In-line or stand alone operation

- Modular upgrade ability

- LDual quick change over bath

- In-line Preheater, In-line Fluxer

- Lead Free Compatible

- SMEMA interface

Aqueous Technologies in the manufacturing of cleaning and cleanliness testing systems for the electronics assembly industry. Aqueous Technologies equipment utilizes our planet's purest substance, water, for the removal of harmful ionic residues. It is our mission to continue developing environmentally conscious equipment which assists manufacturers with increasing product reliability.

PCB Cleaning

Aqueous Technologies

- Focus Wash cleaning technology

- In-built convection and radiant technology drying system

- Real-time predictive cleanliness capability

- SPC data logging

- Automatic De-fluxing system

- Stencil cleaning system

- Removal of fluxes - rosin, water soluble, no-clean

- Removal of eutectic and lead free residues

Aqueous Technologies in the manufacturing of cleaning and cleanliness testing systems for the electronics assembly industry. Aqueous Technologies equipment utilizes our planet's purest substance, water, for the removal of harmful ionic residues. It is our mission to continue developing environmentally conscious equipment which assists manufacturers with increasing product reliability.

Stencil Cleaner

Aqueous Technologies

- Removes all solder pastes and uncured SMT adhesives

- Wash solution is filtered and recirculated (closed-loop) with built-in solder paste trap and filtration system

- Rinse water is filtered and re-deionized and recirculated (closed-loop)

- Removes all solder pastes and uncured SMT adhesives

Our company has earned accolades for providing Vapour Degreaser to the clients. By making use of quality-approved components offered range is manufactured utilizing latest manufacturing techniques in accordance with set quality standards under the guidance of our experts. This product is offered in different specifications to fulfill the broad needs of the clients.

Vapor degreaser

CC Hydrosonics

- Ruggedness

- Simple installation

- High performance

- Small batch applications

- Optical lens cleaning

- Electronic devices

- Rework areas

Desktop Solidering Robot

Our latest desktop soldering robot J-CAT LYRA is equipped with a high level of functionality designed to improve the overall quality of soldering, The J-CAT LYRA is a new soldering robot with significantly improved base operational features, increased usability, and durability. Advanced Temperature Settings Iron tip temperature can be set individually for each soldering point within the same program. As a result, high-quality soldering of components with different heat capacities, reliable filling of through-hole and perfect back fillets can be achieved.

Robotic Soldering J-CAT LYRA

Apollo Seiko

- Easy setting of the soldering conditions

- Advanced Temperature Setting Control

- Approach Function

- Iron unit by electric ARC-5000. The iron unit angle can be changed to any angle

- APN-05, Ultra Small N2 Gas Generator

- Supports dual iron feeder option

Setting industrial Standard

Apollo Seiko Provides soldering solutions for all sectors of automation starting with hand soldering through complete pass-thru conveyorized systems. The L-CAT EVO is a 4 axis Gantry robot for table-top or in-line use. A 30-watt laser diode or an automated iron unit can be utilized to provide the best technology to meet your application requirements. The Luna & Terra controllers can be easily integrated into dial table or conveyorized work cells providing low cost solutions in single or multiple unit scenarios. These machines have a wide voltage input range to provide easy installation at all your global facilities. The N2 Flow unit provides a high-powered, small footprint solution for lead free low volume applications.

Robotic Soldering L-CAT-Neo 4430

Apollo Seiko

- Designed for In-line and Bench Top use

- 4 axis gantry system for inline use

- Non-contact laser soldering unit

- Twin slide shuttle for continuous operation

- Dual soldering heads for higher throughput

- In-built solder fume extraction unit

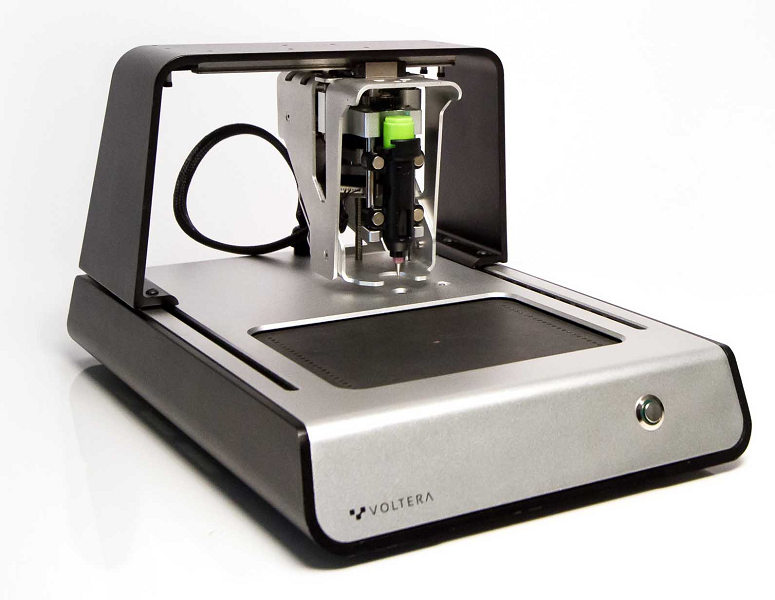

Electronics Prototyping that moves at the speed you need.

The “V-One” all in one PCB Printer, Paste dispenser and reflow. Create PCBs in a jiffy. Easy To Use Software. Creates Custom Circuits. Built for Engineering. Prints Boards on Desktop. Board Assembly Simplified. PCB Printing on Desktop and will help you explore new materials and substrates.

V-One PCB printer

Voltera

- Assemble your boards in half the time.

- Skip the soldering iron

- Forget the stencil.

- A built in heated platform (Reflow)

- Design with two layers and easily make connections without compromises.

Automatic Process.

The Solder Recovery System EPS range of equipment provides a closed environment system for the recovery of solder from the solder dross produced during the wave soldering process. The new SRS 500 is a unique new concept to recovery solder from dross. This system is designed to be a standalone unit which can operate at the convenience of the user company, running off a single phase power supply and connected to the wave or plant exhaust system.

EPS SRS 500

EPS

- n Significantly reduces your Soldering Costs.

- Can be used for both Lead and Lead Free Solder.

- Useful for Dross from 1 Kg to 5 Kgs.

- Totally Automatic Process.

- Can be used if you have multiple Wave Soldering Machines.

- No Need of Dross-Reducing powders or wave oil in your process.

- Increases the effectiveness of wave soldering machine by reducing shorts.

- Cycle time only 50-70 Minutes.

- Can be used for Hot Dross as well as Cold Dross.

- Can recover 60-85% solder from dross, which reduces consumption of Solder.

- Reduces De-drossing time by 75%.

- Patented Technology.

Thermal Profiler

The “V-One” all in one PCB Printer, Paste dispenser and reflow. Create PCBs in a jiffy. Easy To Use Software. Creates Custom Circuits. Built for Engineering. Prints Boards on Desktop. Board Assembly Simplified. PCB Printing on Desktop and will help you explore new materials and substrates.

Thermal Profiler

KIC THERMAL

- Compact — Accurate

- Ease of Use Graphical Interface

Conformal coating

As electronics continually become embedded into an endless variety of products, the need for high-precision conformal coating is greater than ever before. Automate complex coating processes, monitor process parameters and switch spray patterns without interruption. The MYC50 gives you powerful, software-driven process fl ows that ensure years of productivity for even the most complex printed circuit boards.

MYC50

Mycronic

- Fast and stable operation

- Automated spray pattern changeovers

- Flexible multi-axis control for complex processes

- Powerful process controls for enhanced quality

- Barcode-defined program selection

Under fill, Edge Bonding & Corner Fill Dispensing System

Axxon brief introduction founded in 2008, axxon has carved a reputation for itself as a leading manufacturer in the field of automated fluid dispensing, jetting and conformal coating system. we dedicated in designing and manufacturing full line of machines for sealing dispensing, conformal coating, potting, jet underfill, encapsulation and other precise dispensing, crossing industries from smt/ems, household appliance, green energy, automotive, military, semiconductor and medical equipment.

Under fill, Edge Bonding and Corner Fill Dispensing System

AxxonAuto

- Assemble your boards in half the time.

- Skip the soldering iron

- Forget the stencil.

- A built in heated platform (Reflow)

- Design with two layers and easily make connections without compromises.

Potting Solutions - PR70

Potting Solutions - PD44

Graco excels in innovative fluid handling solutions for in-plant manufacturing. Their high-quality sealants and adhesives cater to diverse manufacturing needs, emphasizing precision and reliability. Graco empowers industries with cutting-edge products, ensuring consistent, high-performance results across automotive, aerospace, electronics, and other sectors. Their solutions facilitate seamless application, contributing to the production of durable and reliable goods.

Potting Solutions

GRACO

PR70

- 2K MMD from 1:1 to 24:1

- Shot Size from 2 cc - 70 cc

- Shot and ratio accuracy of 1%

- Configurable system for Ratios, Materials or Operating conditions

- Handle Low to High viscosity

- Handles Epoxy, PU, Silicones etc.

- Auto Refill / Heating / Recircualtion options available

- SS Tank / Agitator Option available

PD44

- 2K MMD from 1:1 to 24:1

- Accurate Small Shot capability from 0.005 - 5 cc

- Handle Low to high viscosity

- Handles Epoxy, PU, Silicones etc.

Cutting Edge Technology

GENITEC Technology, founded in 1993 and certified to IOS 9001 in 2001, has excellent experience in developing high-tech intelligent equipment for SMT and PCB assembly automation industry. Having established modern factories and maintenance service centers in both Taiwan and China, now we are actively setting up a global service network to provide the best service for our customers world-wide. Facing the keen competition in 21st century, GENITEC Technology continues to spend more efforts on innovation and developing new leading-edge technologies with professional and international macro-views. The company continues to cultivate talented engineers by offering state-of-the-art training programs and introducing new technologies to keep their professional knowledge always updated. Maximizing customer satisfaction is GENITEC’s commitment. GENITEC Technology is the best partner of your business. We offer a broad range of Equipment to ensure the best and complete service for electronic industry Automatic PCB Separator, SMT related equipment, PCB equipment, Automation control system equipment and UPS&AVR

GAM330 MODEL

Genitec

- Equipped with high-speed CCD vision alignment system in all series of products to enhance the precision in cutting and efficiency in operation.

- Use high-speed spindle with small cutting stress to precisely cut PCB of any shape.

- Provide dual worktables for placing and cutting PCB in parallel to enhance the efficiency of operation.

- Patented dust collector with low noise and high efficiency. Easy to clean and maintain.

- Windows OS and window-based interface panel. Safe, stable, easy to learn and operate.

Laser Marking

PCB Laser Marking Machine is designed for bar code marking, 2D codes and characters, graphics, and other information on any kind of printed circuit board. Integrated with high-performance CO2 / Fiber laser source, import high-pixel CCD camera and micron-level mobile module, PCB. No link is required for laser marking

Inline Laser Marking

Laser Marking

- Fast Marking Speed.

- High Precision Marking.

- Compatible with Photoshop, CORELDRAW, AutoCAD and other CAD software.

- Low Energy Consumption.

- Flexible Structure.

- High-quality laser beam, small focusing spots and well-distributed power.

- High-pixel CCD camera makes automatic positioning, identification and feedback reporting come true.

Auto Screw Lock

The main function: Suitable for automatic screw fixing on the products such as mobile, Ipad etc., Includes CCD correction, auxiliary teaching screw coordinate point (previously required manual visual positioning, large error) CCD intelligently screens defective screw holes (covered by shrapnel, blocked holes, and incomplete holes)

SC-560 Auto Screw

Brady Auto Screw

- With intelligent detection function, it can detect leaked lock, floating lock, sliding teeth, etc.

- Strong flexibility, the standard universal fixture is suitable for screw locks of a variety of models

- Strong versatility, can adapt to M1.0~M5 screw locks

- Compact and easy to put into the production line

- The side wall is close to the lock

A reliable partner in your progress

© 1997 - 2020. Accurex Solutions Pvt. Ltd.